In the fight against water infiltration, Stevanato had the chance to specialize also in the waterproofing with polyurea.

For this purpose, it uses one of the most modern existing materials: a resin-based sheath that is used by spraying, is rapidly hardened, is waterproof and contains no solvents.

This waterproofing can be hot sprayed with suitable pumps or applied cold using a roller, brush or sprayed.

The waterproofing with polyurea is perfectly adherent, therefore achievable on difficult surfaces such as:

- steel

- concrete

- reinforced concrete

- terracotta

- iron

- bituminous sheaths

- stoneware

- wood

- grit tiles

- spray polyurethane or panels

- polystyrene

The polyurea is applied by using a high pressure and high temperature bi-mixer pump. As soon as the mixture is sprayed, it catalyzes within a few seconds.

During the waterproofing operations with polyurea, the application surface is checked beforehand and it must preferably be rough and dry (maximum humidity 15%). Otherwise, it is prepared in order to obtain a perfect adherence of the new applied material, such as by spreading a primer coat before the application, with the exception of the old bituminous sheaths.

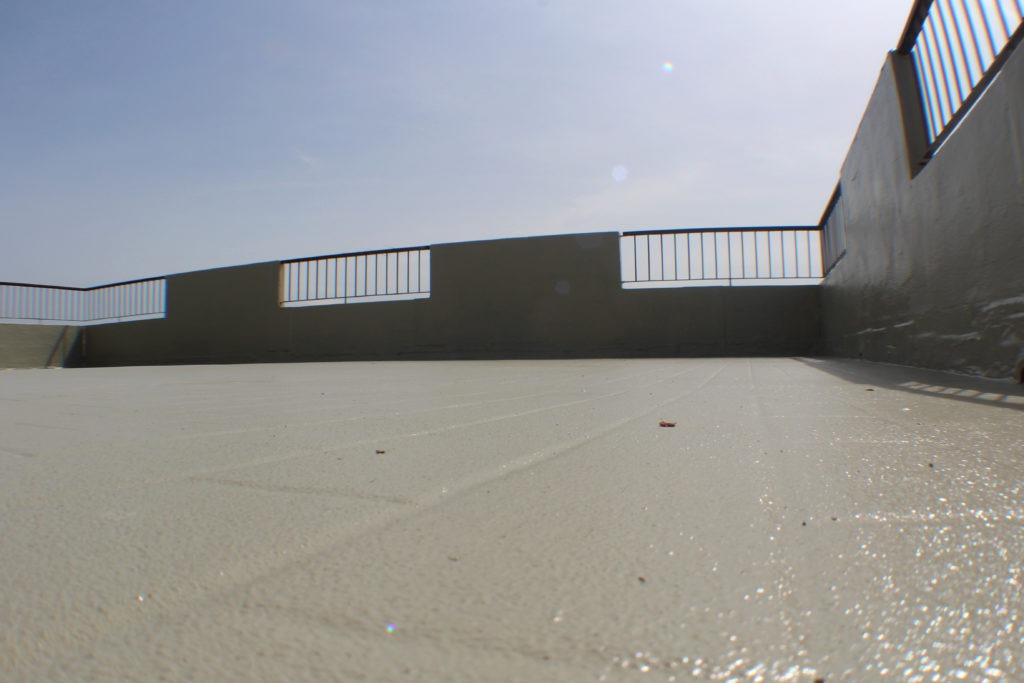

The fields of application of waterproofing with polyurea are:

- walkable or drivable plains

- outdoor and indoor industrial floors

- primary containment tanks for purifiers, underground or above ground

- anticorrosive coating for secondary containment tanks for special plants

- sidewalks, tunnels, road bridges

- open-air fluvial channels

- swimming pools and hot tubs